Chocolate Shell Moulding Line

Alpy Full Automatic Chocolate Shell Moulding Lines are produced with 470x200x30 mm, 600x200x30 mm and 800x245x 30 mm mould dimensions.

Moulds are pushed by the pims on the chain and automatically pass through all stations and ready products for packaging go out from the exit band. Unloaded moulds firstly enter to the unempty mould control and separation system, unempty moulds are taken from the production line and the empty moulds are fed to the production line. And then empty moulds enter to the mould heating tunnel again. Stations on the full automatic chocolate shell moulding line is changable depend on customer’s demands.

Main chain drive, depositors pistons, depositors valves, mould lifting units, shell making groups, cooling tunnels chain drives, cooling tunnels mould sliding systems and mould unloading group are servo motor controlled.

Machine capacity for shell products are 14-16 moulds/minute and for one-shot products are 18-20 moulds/minute depending on product dimensions and weights.

Elevator type shell cooling tunnel has 20+20=40 flats and each flat has 2 mould. Total capacity is 80 moulds.

Elevator type filling cooling tunnel has 20+20=40 flats and each flat has 4 mould. Total capacity is 160 moulds.

Elevator type main cooling tunnel 40+40=80 flats and each flat has 6 moulds. Total capacity is 480 moulds.

Standard Stations On The Full Automatic Moulding Line

- Mould Heating Tunnel

- One-Shot Depositor, Vibration Unit

- Shell Group

- Horizontal Shell Cooling Tunnel

- Elevator Type Cooling Tunnel

- One-Shot Depositor for Filling

- Vibration Unit

- Elevator Type Filling Cooling Tunnel

- Mould Heating Tunnel 2

- Chocolate Depositor

- Vibration Unit

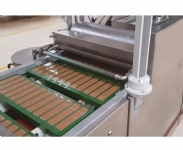

- Mould Scrabing Drum

- Elevator Type Main Cooling Tunnel

- Mould Twisting Group

- Mould Unloading Hammers unit

- Unempty Mould Controll

- Seperating Group

- Exit Band

Optional Stations On The Full Automatic Moulding Line

- Extra single or One Shot Depositors

- Vibration Groups

- Local Cooling Tunnels

- Granule Spreading Equipment

- Whole Nut Dosator

- Biscuit Feeding Drum

- Wafer Feeding System

- Chocolate/Cream - Granule/Whole Nuts Mixer.

Shell Moulding Line Technical Information Table

| AKH-470 | AKH-600 | AKH-800 | |

| Mould Dimensions | 470 x 200 x 30mm | 600 x 205 x 30mm | 800 x 245 x 30mm |

| Machine Capacity For One Shot Products | 16-18 Mould /Min. | 16-18 Mould /Min. | 16-18 Mould /Min. |

| Machine Capacity For Shell Products | 12-14 Mould /Min. | 12-14 Mould /Min. | 12-14 Mould /Min. |

| Chocolate Depositor Amount | 1 pcs. | 1 pcs. | 1 pcs. |

| Pistons on Double Part Depositor | 48pcs. | 60pcs. | 100pcs. |

| One Shot Depositor Amount | 2 pcs. | 2 pcs. | 2 pcs. |

| Pistons on Double Part Depositor | 48 + 48pcs. | 60 + 60pcs. | 100 + 100pcs. |

| Vibration Amounts | 3 pcs. | 3 pcs. | 3 pcs. |

| Local Cooling Tunnel Amount | 2 pcs. | 2 pcs. | 2 pcs. |

| 1st Local Cooling Tunnel Power | 10 HP | 12 HP | 15 HP |

| 2nd Local Cooling Tunnel Power | 15 HP | 20 HP | 25 HP |

| Main Cooling Tunnel Power | 2 x 15 HP | 2 x 20 HP | 2 x 25 H |

Please note that we offer 12 months guarantee period for the defaults sourced by Alpy Machinery.

For special needs or production capacity please write us.

Machine Video Get A Quote