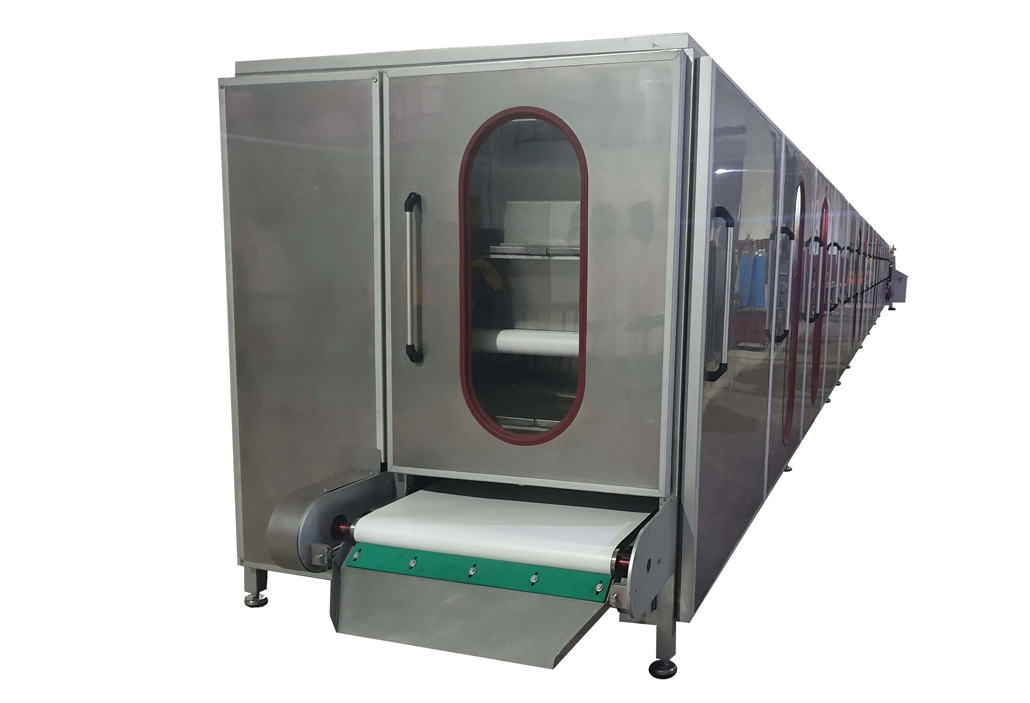

Rotary Depositor Drop Chocolate Line

The rotary depositor drop chocolate line is developed by our R&D and technical departments. This new technological depositing system achieves higher output product quality and capacity than standard drop chocolate production lines.

Designed to outshine standard drop chocolate lines, our rotary depositor promises not just higher output, but a symphony of quality and capacity.

The production line includes depositor groups and three flat cooling tunnels. The cooling tunnel upper flat is water-cooled from the bottom and air-cooled from the top, while the other two flats are air-cooled only.

According to client demands, several depositors with different product center intervals can be fixed on the same line.

Standard Drop Chocolate Production Lines

Alpy has three models, and they are adjustable to your needs. For general information, check below.

ARD-800/300

The ARD-800/300 model has a 300 kg/hr capacity. 800 mm depositor width, 3 flat cooling tunnels, and each flat is 7.500 mm in length.

ARD-800/1000

The ARD-800/1000 model has a 1000 kg/hr capacity. 800 mm depositor width, 3 flat cooling tunnels, and each flat is 22.440 mm in length.

ARD-800/2000

The ARD-800/2000 model has a 2000 kg/hr capacity. Line has an extra flat with a second rotary depositor. Each depositor is 800 mm wide. There are 4 flat cooling tunnels, and each flat is 23.400 mm in length.

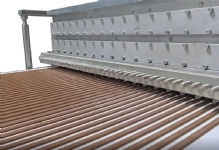

*It is possible to have different diameters and shapes of chocolate drop lines by changing the speed of the rotary depositor and tunnel conveyor independently (between 9000 pcs/kg and 20.000 pcs/kg).

The roving conveyor belt used in the tunnel prevents the conveyor from moving to the right or left, so there is no dispersion of the products.

In our PLC-controlled machine, depositor speed, depositor temperature, internal pressure, cooling tunnel speed, and temperature can be easily adjusted from the control screen and recorded in the recipe section.

What is rotary depositor drop chocolate line?

The Rotary Depositor Drop Chocolate Line represents the latest technology globally for producing uniform and high-capacity drop chocolates, button chocolates, and stick/chunk chocolates. Alpy Machinery stands as the sole producer of this line in Turkey and one of only two producers worldwide. This line allows for the production of both compound and real chocolate on the same platform, accommodating various viscosity values

For more info or quote request for state of the art drop chocolate line with rotary depositor please contact us from info@alpygroup.com

More information about Chocolate Drop Line

The rotary depositor drop chocolate line is an advanced technological depositing system designed by Alpy R&D and technical teams. This innovative production line surpasses standard drop chocolate lines in terms of both output and product quality. It includes depositor groups and three flat cooling tunnels, with the upper flat being water-cooled from the bottom and air-cooled from the top, while the other two flats are air-cooled only.

The system allows for customization based on customer demands, enabling the fixation of several chocolate chip depositors with different product center intervals on the same line. There are also standard drop chocolate production lines with different models and capacities, such as the ARD-800/300, ARD-800/1000, and ARD-800/2000.

Standard stations on the line:

- Rotary depositor for chips chocolate

- 3 flat cooling tunnel

- Chiller water cooler

- Second rotary depositor for button chocolate

- Chunk extruder and 2 pcs servo motor-controlled guillotine group

- Chocolate chips

- Chocolate chunks

- Drop chocolates